Which technologies will you see in action on the event?

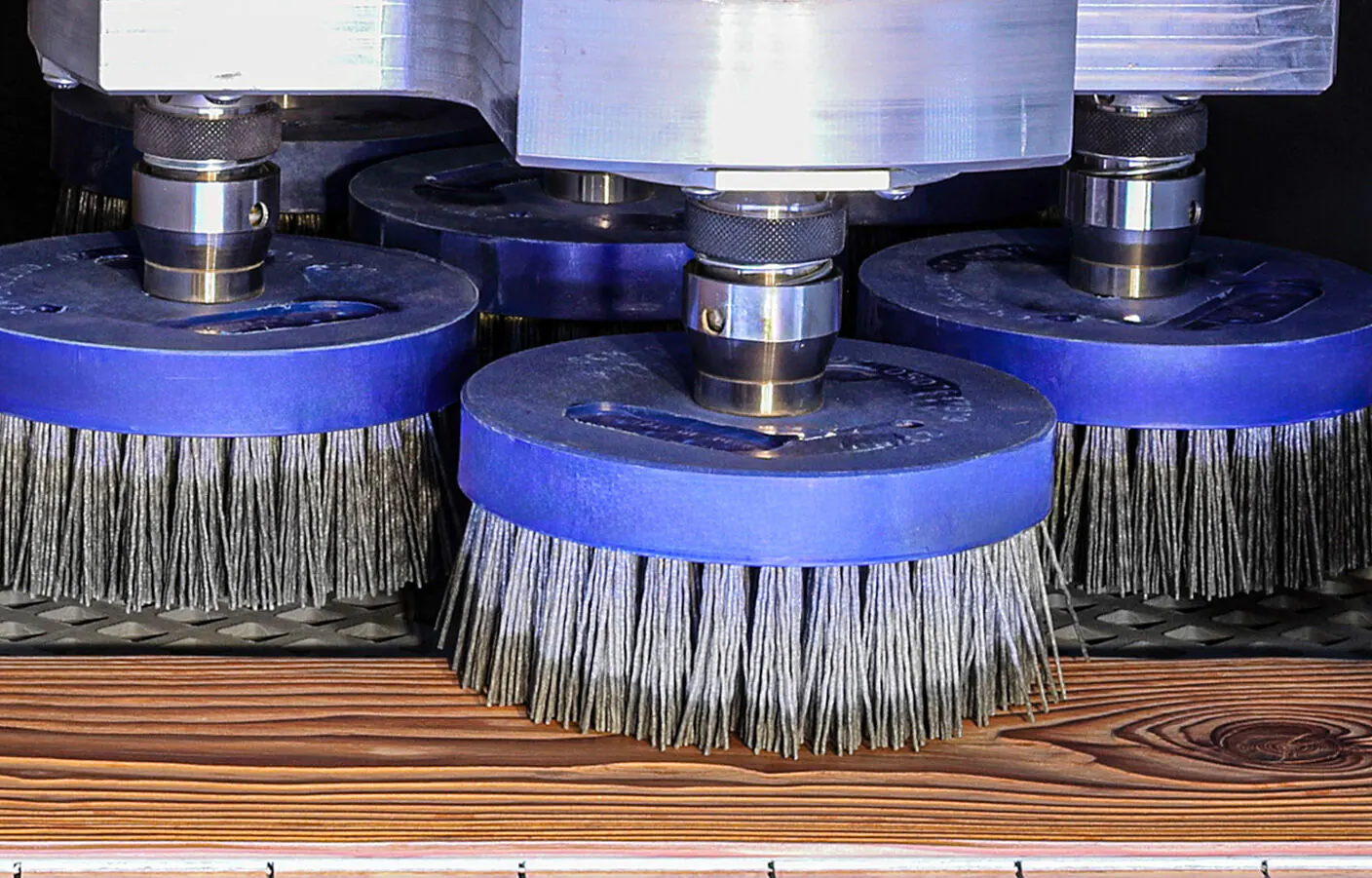

THE MOST EXTENSIVE SANDING-CALIBRATING RANGE

Every production requirement is met with the large number of models available, from the narrowest and most compact machine model to the widest and high performance one, to support even the most intensive workloads.

EASY TO USE

Maestro active HMI is simple and safe to use, even for less experienced operators.

BESPOKE FINISHING FOR EVERY REQUIREMENT

The most exclusive and sought-after effects on panels, wooden floor, windows and doors as well as kitchen cabinet doors in line with the latest market trends are achieved with our calibrating-sanding solutions.

NO MACHINING LIMIT

All possible operations can be performed in a single machine solution, by integrating the extensive range of operating units available on dmc like: Carving, Hand-scraping, LaserCraft, Superfinishing and Planetary.

HIGHLY FLEXIBLE

The wide range of advanced technological solutions and modular structures, that can be fitted with up to 10 working units, allow a large number of configurations.

CLEANER & HEALTHIER ENVIROMENT

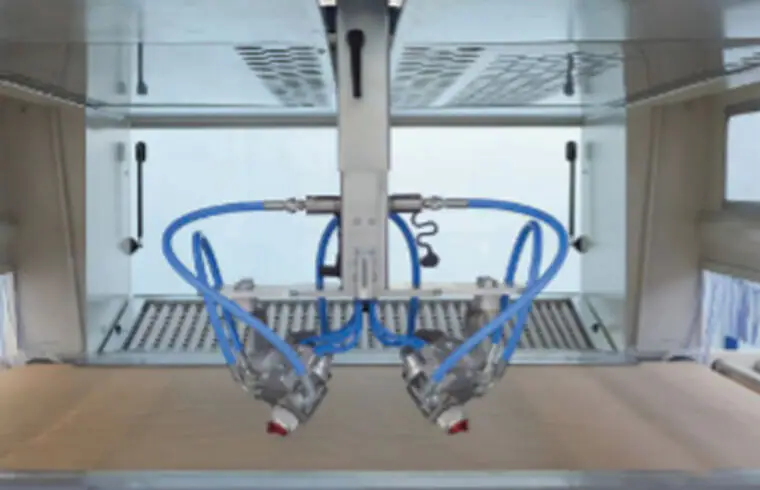

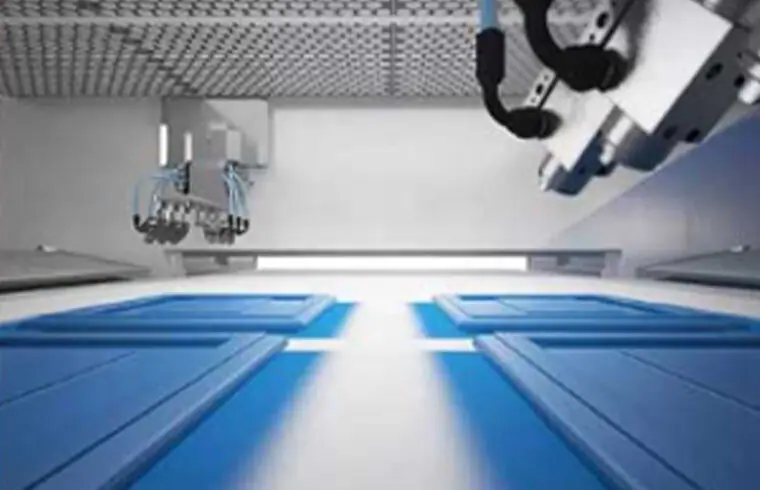

spraying booth designed to contain over spray and convey the exhaust air through dry filters with integrated suction system

FLEXYBILITY

quick spraying guns change for an easy change of spraying cycle and conveyor system with high absorbent paper protection, ensuring fast switching from one application to another

OPTIMIZATION

automatic laser reading of the working width of the loaded parts to limit the waste of paint

SAFETY

external control panel to guarantee safe execution even for solvent based varnish application

QUALITY & PRECISION

industry leading smooth motion of spraying thanks to the arm mounted on precision linear guides with brushless drive

FULL CONTROL

our powerful software Opti-spray controls the machine parameters, adjusting the spraying guns according to the data scanned at the infeed and stores working parameters into specific recipes.

We look forward to welcoming you in SCM Adria’s Technology center!

SCM Adria

Gmajna 13, 1236 Trzin, Slovenia

+386 1 320 17 40